Home Fabrics Manufacturing Process

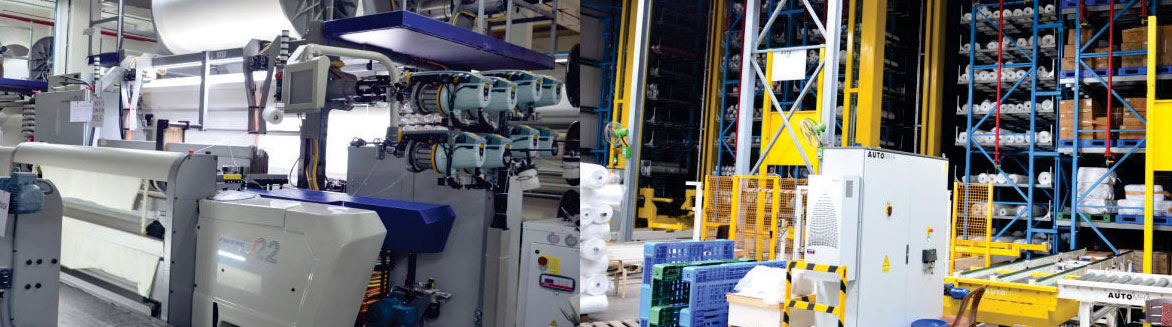

Our state-of the art factories located in Tarapur and Vapi are vertically integrated producing jacquard decorative fabrics for drapery, upholstery, wide width sheers and embroidery. Our Tarapur set up has our first robotic warehouse. We produce more than 1.5 lakh metres of fabric every month. All our manufacturing processes are integrated under one roof to ensure timely delivery.

Our vertically Integrated, state-of-the-art, in-house manufacturing facilities, consist of:

Yarn preparatory : Fancy Yarns, Chenille Yarns, Twisting, Texturizing, Sizing,Warping, Automated Yarn dyeing.

Weaving : Decorative jacquards, Novelty plains, Textures, Wide width and fancy sheers, jacquard velvets and plains. Largest Velvet Manufacturing furnishing Mill in India.

Embroidery : Multi head embroidery with fancy, cording, ribbons, sequins and laser applique attachments.

Fabric Processing : Automated fabric dyeing consisting of modern, Italian auto dispensing technology.

Special Finishes : Calendering, Decatising, Sanforizing, Pleating, Crushing, Fire Retardant, Soil & Water Repellent coating, Bonding / Lamination, 3 pass blackout coating, Soft Touch Airo, all under one roof.

Printing : Italian Digital Printing Technology.

Cut & Sew : In-house stitching facility.

Robotic Warehousing : State-of-the-art,Italian, fully automated robotic warehousing facility.

Design Studio : Team of 35 designers constantly developing new designs / qualities / techniques using Italian / British Trend Forecasts.